The blast machine is the heart of the pressure blasting system. Attention to the proper configuration and compatibility of the machine’s components is crucial and ensures maximum blasting efficiency. Thanks to Clemco’s wealth of experience and commitment to innovation, Clemco products deliver high levels of reliability, longevity, and safety in abrasive blasting.

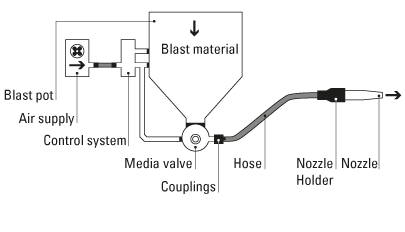

Pressure blast systems - from blast pot to nozzle

System components

System configuration

The proper selection of all system components in a blast machine is crucial to achieving the highest level of efficiency. Blast machine construction, capacity, media valve type, hose and nozzle, properly selected, will provide the ideal solution for any job requirement.

Our staff and distribution network can develop the optimal blast machine configuration for any application.

Blast Pots

With both 20- and 40-litre machine sizes, we offer very compact and thus extremely portable blast pots with a ½” pipe cross section that is perfectly suited for smaller jobs that need the sandblaster to be transported easily. For our larger blast pots, we use 1 ¼” pipe cross sections that have established themselves as the standard in terms of performance and mobility. Because of the larger pipe cross section, there is less pressure loss due to friction in the pipes. In this range, we offer blast pots between 50 and 300 litres, or our BIG Clem with 4500 litres that offers an extremely large blast media volume, for example.

All our blast pots are suited for the usual types of blast media and hence are used for a wide range of applications. We can offer appropriate solutions even for very fine blast media that often does not flow well. Generally speaking, abrasive blasting is referred to as “sandblasting”, but sand is no longer commonly used as the actual blast media for health reasons.

A question often asked regarding sand blasting has to do with the appropriate compressor so the blast pot can be used efficiently. Associating the correct compressor with the machine size is a frequent mistake, because the necessary compressor is based rather on the size of the respective nozzle and the corresponding air throughput. Therefore, it does not matter whether a 100- or a 200-litre blast pot is used for actual sandblasting.

Our blast pots are tested for proper functioning before they are delivered and can be used immediately upon delivery without the need for additional adjustments. Each blast pot receives a CE certificate, and thus meets the most recent standards. In the selection of materials, we place great importance on quality and a long service life. In order for our blast pots to remain in operation without greater investments, we also guarantee the supply of spare parts, whether they are to replace worn ball valves or individual parts of a valve.

When you choose one of our blasting systems, in addition to the blast machine, you will receive a complete system that contains the other equipment such as the hose, nozzle, and protective equipment. This is because our blasting systems are perfectly suited as first-time equipment packages so you do not have to worry about selecting the right package.

Remote control systems

Precise operational control and safety is the hallmark of Clemco remote controls, which immediately start or stop the blast stream whenever necessary. The operator controls the blast stream independently at the nozzle, an indispensable safety feature. The blast pot can be emptied and reloaded with the engagement of the control handle, which functions on a pneumatic signal system. For longer hose lengths, Clemco recommends its low-voltage, electro-pneumatically controlled option.

Abrasive metering valves

- Optimum blast stream

- Precisely-controlled abrasive content

- Long lifetime

- Simple maintenance

- High efficiency

Clemco media valves dispense abrasive in an even, regulated flow, offsetting irregularities during pressurization and depressurization, making for consistent ease of use. Pneumatic controls respond far more quickly than manual ones, increasing operator safety through immediate start/stop control of the blast stream. The „fail-to-safe“ feature of control handle release ensures that, should the operator drop the blast hose or encounter any other problems, the blast stream stops immediately. An optional Abrasive Cutoff Switch can be added to control the media flow at the handle, allowing for an air-only blowoff stream for cleanup.

Blast hose

Nozzle holders and couplings

The couplings and nozzle holders are made of high-quality, durable materials such as nylon, brass and aluminum, to guarantee peak levels of functionality and safety. These components are designed to function in any condition on any job site.

Blast Nozzles

Clemco’s engineers consistently pursue one objective in the development of blast nozzles: greater performance with a minimum of wear. Correspondingly, Clemco blast nozzles come in a wide variety of different liners and nozzle jackets to suit any application and abrasive media. Each nozzle type has been formulated for a specific area of blast application, and the components and construction of each nozzle reflect this specificity. The available air volume, size of the workpiece, abrasive type and required surface profile all factor in critically to the proper nozzle selection.